New Container Vessel (New Container Vessel Working Group)Newly built autonomous vessel aiming for autonomous navigation by 2040

Project overview and development status

Consortium members (as of April 2024)

- MTI Co., Ltd.

- Japan Marine Science Inc.

- Ikous Corporation (in Japanese)

- Furuno Electric Co., Ltd.

- Tokyo Keiki Inc.

- Nabtesco Corporation

- Bemac Corporation

- JRCS Co. Ltd.

- Space Compass Corporation

- Japan Marine United Corporation

- Eizo Corporation

- Sunflame Co., Ltd.

- Weathernews Inc.

Others

Project overview

With MEGURI2040 Stage 2 aiming for social implementation, a new 700 TEU (twenty-foot equivalent unit) container vessel is being developed for automated navigation that will enable continuous commercial navigation after demonstration testing has been completed. In concrete terms, this will lead to the realization of future autonomous navigation in which navigation from wharf to wharf is fully automated, the ship’s engine plant is remotely monitored by an onshore Fleet Operation Center, and navigational support reduces the crew’s workload. If this is successful, it can be seen addressing the so-called “2024 issue” in logistics (labor shortages resulting from caps on overtime by truck drivers that took effect in 2024) and helping to strengthen logistics in Japan. The Fleet Operation Center will also be staffed by ships’ crews, creating a new work-style option for crew members who currently are unable to return home at the end of each workday. Specifically, development will include camera sensors that can make visual observations in place of crew members, functions to improve the reliability of sensors, give-way planning functions that use sensor data, ship control functions that achieve seamless operations from leaving the wharf to ordinary navigation to docking, functions that allow mooring operations to be carried out with fewer crew members, functions to detect abnormalities in the ship’s engine plant so that the ship’s equipment can be monitored from shore, and ship-to-shore telecommunications functions that operate continuously and economically. The new container vessel for which these functions are being developed is being built by Kyokuyo Shipyard Corp. and is scheduled to be put into service in roughly October 2025, after which autonomous navigation is scheduled to be implemented for demonstration testing and commercial navigation. Two types of Fleet Operation Centers – a permanent type and a mobile type – are also being developed.

Development status (as of April 2024)

Looking toward the October 2025 service launch, the basic equipment design has been completed and more detailed design and equipment development are proceeding. To move forward with social implementation, the consortium is working with Nippon Kaiji Kyokai and overseas ship classification societies to evaluate and inspect the automated navigation system being developed to confirm and certify its safety. Specifically, a risk assessment based on the basic design for autonomous navigation is being carried out to identify functional requirements. The companies developing each piece of equipment will move forward with their development based on the requirements identified. To create a simulation environment for the evaluation and inspection of the equipment that is developed, a simulation model of the actual ship is being built to measure the ship’s operational functions using a model hull in a water tank. The consortium has finalized the functions that need to be built into the vessel and has begun making detailed designs. The testing of individual pieces of equipment that have been developed is scheduled to start in April 2024, followed by the equipment being connected to a simulator for integrated testing on land from September 2024.

Development highlights

Building on MEGURI2040 Stage 1, which was highly recognized globally, the consortium is aiming not only to be a demonstration but also to achieve the world’s first automated navigation of a medium- to large-sized vessel in commercial navigation from unberthing to berthing. As a first step, the lookout function, currently performed by two crew members on a large vessel, will be able to be handled by one person, with development continuing to be able to have no lookout staff on the bridge as crew staff become fewer in number in the future. In addition, human error is currently responsible for roughly 70% of maritime accidents, and equipping ships with this system will contribute to safe navigation by reducing human error. An engineer at the Fleet Operation Center will be able to use onshore support functions to monitor the onboard engine plants of multiple vessels, with a system being built that will enable one engineer onboard to respond to irregularities. Specifically, by adding situational monitoring sensors and building a system that can use the collected sensor data to predict equipment irregularities before they occur, it will be possible to perform equipment maintenance when the ship is docked and before problems occur, thereby reducing the incidence of problems at sea. This will be able to achieve both safe navigation and reductions in crew workloads.

Looking ahead

The equipment being developed is scheduled for stand-alone testing from April 2024 and then to be connected to a simulator for integrated testing from December 2024. Construction of the vessel is scheduled to start from early 2025, with the vessel to go into service from October 2025 for demonstration testing of automated navigation while on commercial routes. This will be one of the world’s first uses of comprehensive automated navigation of a vessel from unberthing to berthing in congested sea lanes. At the same time, the London-based International Maritime Organization is working to create an international treaty for automated navigation, bringing global attention to the MEGURI2040 project. In addition to improving work environments in Japan’s coastal shipping, this world-leading initiative will help to make Japan’s domestic logistics more resilient and showcase technologies first developed in Japan to the rest of the world.

Participants’ comments

Yuichi Minemoto (Chief Manager, Electric Group, Basic Design Dept., Design Division, Nihon Shipyard Co., Ltd.)

I am involved in the engineering of telecommunications parts in the automated navigation system, which consists of several parts. My specific responsibilities are examining the arrangement of ship-to-shore telecommunications antennae and peripheral monitoring cameras, and construction shipyard technologies. It is important to resolve issues while coordinating the requests of equipment manufacturers and construction constraints. The companies making the telecommunications parts are not particularly familiar with ship-use equipment, which makes it difficult to make adjustments for installation on a ship but also gives me a sense of satisfaction. The capabilities of a variety of ship-oriented and land-based companies are indispensable for the achievement of autonomous navigation, and examination with a view toward implementation is needed. I also feel a sense of accomplishment when products made for use on land are successfully installed on the ship, and there is a moment of great joy when they work successfully. I look forward to continuing to work on this project.

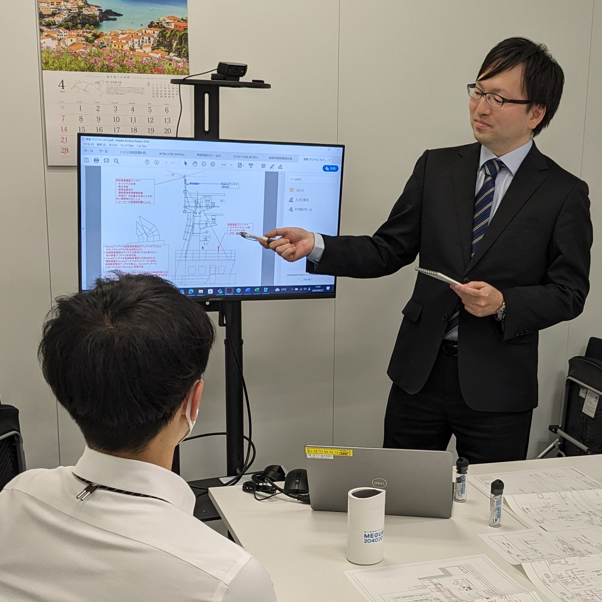

Rintaro Matsushita (Researcher, Simulation Team, Marine Logistics Technology Group, MTI Co., Ltd.)

I am primarily involved in building simulation models to digitally recreate the movement of the ship’s hull. I also do model testing and data analysis to estimate parameters for use in the model. The development of a fully autonomous ship involves many items to be examined, including maneuverability, safety, and linkage with various telecommunications and control equipment. Examining these in advance using a simulation makes it possible to identify and resolve many issues, thereby significantly reducing risks and costs during demonstration testing. I am involved in many development operations needed for the simulation in addition to building the models for this testing, which makes my days very satisfying.